Vibrage

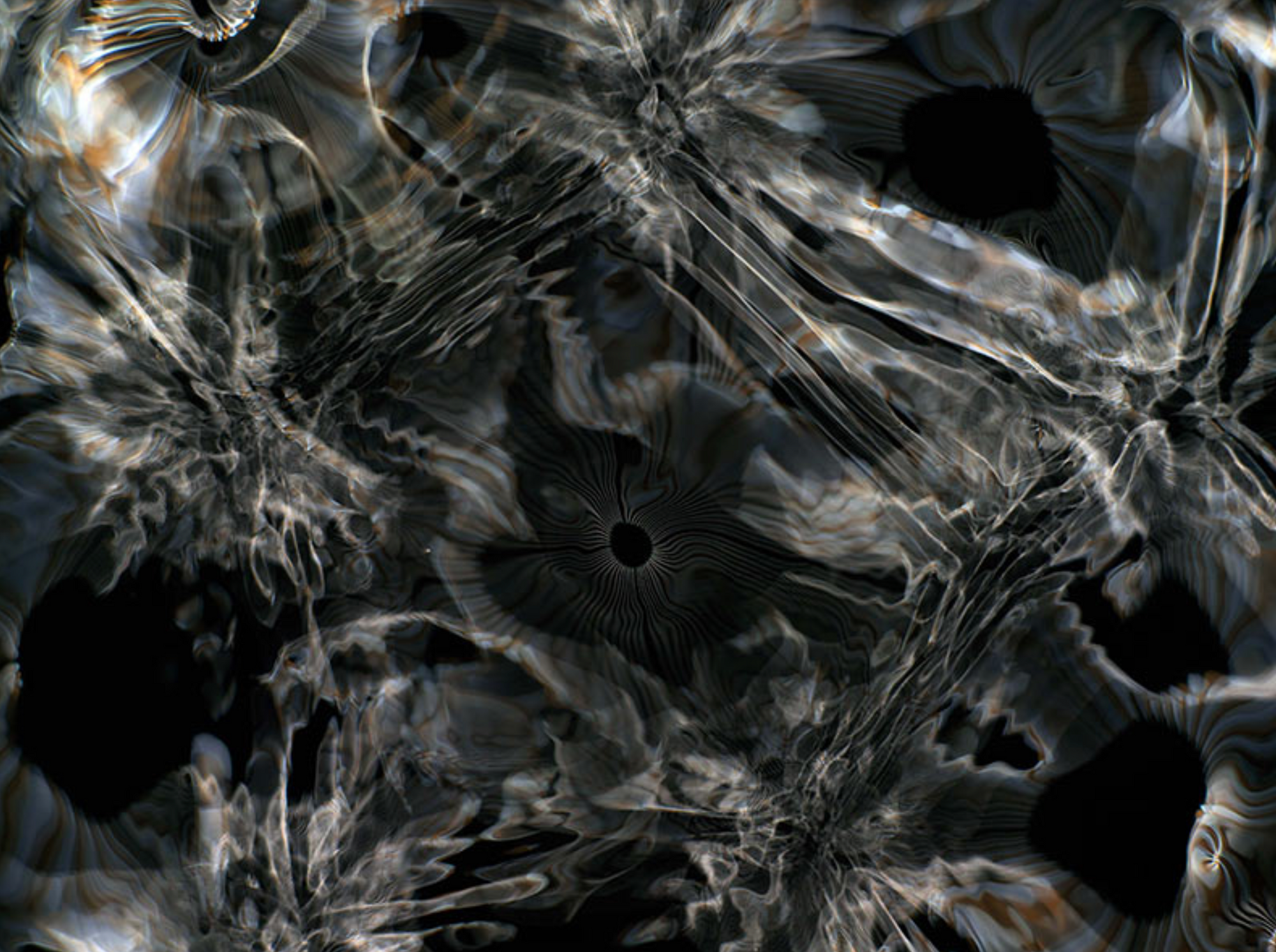

AGING FRAGRANCES WITH SOUND.

MAGIC FOR SOME. SCIENCE FOR OTHERS.

Sonochemistry & fragrance

Vibrage™ is grounded in sonochemistry, a field documented for decades in food science, enology, and advanced material processing. The same principles that accelerate wine aging and improve soy fermentation have been adapted to perfumery with precise protocols: controlled frequency ranges, calibrated resonance vessels, repeatable treatment windows. Development was conducted in Normandy in collaboration with laboratories and validated through independent analyses. The process was patented in 2024 and supported by institutional partners, including Bpifrance. This is not a claim; it is a protected technology with published documentation.

UNIQUELY YOURS

Measured, Reproducible

Every Vibrage™ cycle is logged in laboratory conditions. Frequency, duration, and temperature are controlled, repeated, and archived. Comparative testing, GC-MS, FTIR, NMR, confirmed the absence of degradation in fragile naturals. Blind sensory panels consistently described greater roundness, faster integration, and improved diffusion. Results are reproducible across batches, on both small and industrial scales. The difference with “traditional” inert storage is not ideology but physics: acoustic energy actively drives dispersion and molecular interactions instead of waiting for passive equilibrium.

ALREADY IN USE.

Clean Technology for Perfumery

Classical maceration and maturation demand months of storage, high energy consumption, and large volumes of flammable stock. Vibrage™ reduces time, risk, and waste while delivering perfumes that are chemically more stable and organoleptically more coherent. By applying controlled ultrasound rather than relying on inertia, the process offers a cleaner, safer, and more resource-efficient path to consistency. It is already applied selectively to Première Peau creations not as a gimmick, but as a tool: a documented, tested, and patented innovation to rethink how perfumes are stabilised and aged.

A: Controlled ultrasound waves propagate through the perfume matrix, generating acoustic cavitation. Microbubbles form and collapse, creating micro-agitation, turbulence, and localized high-pressure zones. These conditions accelerate diffusion, improve solubilization of resins and musks, and facilitate reactions such as esterification and Schiff base formation processes that normally unfold slowly during passive maturation.

A: Traditional maturation is largely passive. Molecules equilibrate slowly in large vats held at controlled temperatures. Vibrage™ replaces waiting with reproducible energy input. It reduces the months of inert storage, lowers industrial risk (flammable volumes, energy use), and provides more consistent results, without changing the perfumer’s formula.

A: Development took place in Normandy with laboratory partners, supported by Bpifrance. The process was tested across small-scale (100 mL) and industrial-scale (100 L+) volumes. Every parameter ; frequency, duration, intensity was logged and repeated. Results were consistent across trials, and the method was patented in 2024.

A: No. Vibrage™ does not change the perfumer’s formula. It accelerates physical and mild chemical processes that are already part of natural aging. Independent sensory panels described treated batches as more inetgrated and rounder, while analytical techniques confirmed lower degradation of delicate naturals.

A: Vibrage™ is applied selectively to certain Première Peau perfumes. It is used as a clean technology tool never as a shortcut, always as a method to ensure quality and integrity.